This month we are looking at twin needles – a fantastic little tool for that professional finish.

Twin needles can be used to create parallel and decorative stitches. They are most often used on the hems of knit and jersey fabrics to create a professional finish.

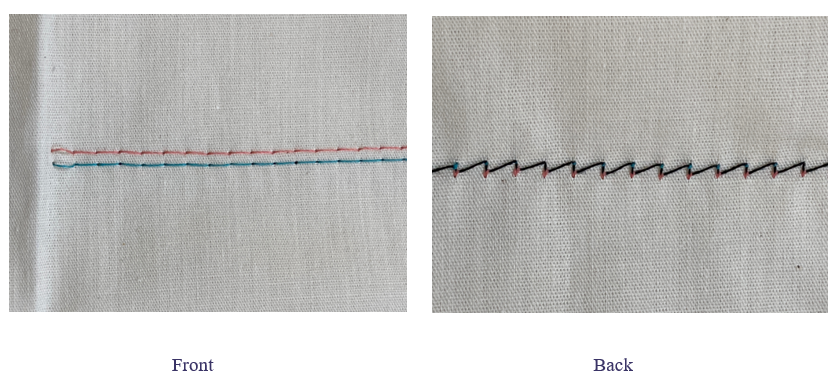

Shop bought knit garment hems have parallel lines of stitching, these are created on a coverstitch machine but you can achieve a similar result with a twin needle.

Using a twin needle also helps to prevent the stitches from breaking because the zig zag stitches created on the wrong side of the fabric add strength. This is important with fabrics that stretches during wear.

Type of twin needles

Twin needles come in different sizes, as in single needles they come in 75s, 80s, 90s and 100. The size indicates the size of the eye, 100 being the largest.

Twin needles also come with various gaps between the needles, 1.6 to 6.0 mm. 3mm is a common size but note the needle must fit inside the presser foot opening and zig zag plate opening.

Different types of needle are available for different fabrics, universal, ball point, stretch, jeans, metafix and embroidery.

The twin needle setting must be selected.

How to use twin needles on Brother sewing machines

On Brother machines the first thread is threaded in the usual way threading in into the left eye of the needle, the second thread is placed on the auxiliary spool holder, threaded alongside the first thread, placed in front of the needle bar and threaded in the right eye of the needle. DO NOT use the machine needle threader.

Test the stitching on a scrap of the fabric you will be using before sewing the real thing, press the hem into place, sewing from the front, place the fabric so the left hand needle just catches the edge of the hem.

Tunnelling means the fabric in between the two lines is raised. Should this happen try adjusting your stitch length and needle tension. Alternatively you can use woven wash away stabilizer underneath the fabric.

by Morag Todd